Extending the lifespan of cylindrical-shaped metal parts often involves electroless nickel coating, a highly effective method. This process uses chemical deposition of nickel-phosphorus or nickel-boron alloys onto metal surfaces without an electric current. Offering superior corrosion and wear resistance along with a uniform thickness, electroless nickel coating is perfect for enhancing the durability of long rollers, cylinders, and pipes. Understanding the benefits of this coating and finding the right metal plating service near Dallas is essential for maintaining your longer parts.

Types of Machinery Utilizing Metal Rollers

Metal rollers are crucial in various machinery, especially in sheet material processing and conveyor systems. Here are seven types of machinery that commonly use metal rollers:

- Sheet Metal Roll Forming Machines: These utilize metal rollers to shape and bend sheet metal into desired profiles and shapes.

- Paper Manufacturing Equipment: Metal rollers are vital in the paper industry for transporting, pressing, and drying paper sheets.

- Plastic Film Extrusion Machines: Metal rollers cool and solidify extruded plastic films in these machines.

- Printing Presses: Essential for ink transfer and paper handling in printing presses.

- Textile Processing Machines: Rollers help in stretching, dyeing, and finishing fabrics in textile machinery.

- Food Processing Conveyors: Metal rollers are used in conveyors to move food products through processing and packaging stages.

- Automotive Manufacturing Lines: Rollers move metal sheets and parts along assembly lines in automotive plants.

Industries Utilizing Metal Tubes and Pipes

Metal tubes and pipes are key components in many industries for fluid and gas transport. Here are five industries where they play a critical role:

- Oil and Gas Industry: Extensively used for pipelines transporting crude oil, natural gas, and refined products. For effective oil and gas pipeline coatings, specialized services are required.

- Chemical Processing: Essential for safely moving chemicals and solvents through production processes.

- Water Treatment Plants: Pipes are crucial for transporting water and wastewater through treatment systems.

- HVAC Systems: Metal tubes transport refrigerants and air in heating, ventilation, and air conditioning systems.

- Pharmaceutical Manufacturing: Used for sterile fluid and gas transfer in drug production.

Benefits of Electroless Nickel Coating

Electroless nickel coating provides numerous advantages, particularly in protecting against chemical corrosion. This coating forms a uniform layer that covers every part of the metal, including difficult-to-reach areas, offering comprehensive protection. The nickel-phosphorus alloy used in this process resists chemical reactions, preventing metal corrosion from harsh chemicals, acids, or other corrosive substances.

The coating can be enhanced with additives like strong abrasives and hardening agents. For instance, a composite diamond coating contains microscopic diamond particles that increase hardness and wear resistance, making metal parts more durable in high-friction and abrasive environments.

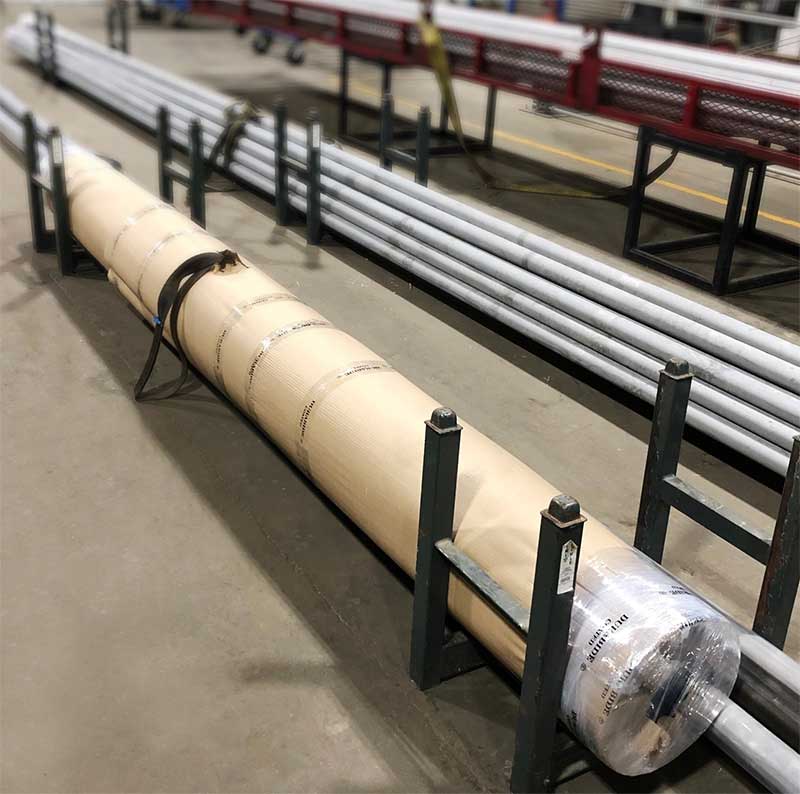

Challenges in Metal Plating for Long Parts

Coating long rollers, cylinders, tubes, and pipes poses challenges, particularly due to the size of metal bath tanks used in the plating process. Many facilities have tanks that are too small for parts longer than 3-4 feet, which complicates achieving a uniform coating. Typical tank sizes are 24” x 36” and 24” x 48 inches.

Duratech Processes Inc: Your Solution for Long Parts

If you need a metal plating service near Dallas capable of handling longer parts, Duratech Processes Inc is the solution. Located in Texas, Duratech has metal bath tanks large enough to accommodate parts up to 40 feet long. This makes them ideal for oil and gas pipeline coatings, as well as other applications requiring long, cylindrical metal components.

Duratech also specializes in metal plating for steel in Midland TX, serving offshore oil drilling operations in the Gulf of Mexico to ensure high-quality coatings for maximum durability and longevity.

Investing in electroless nickel coating for your long rollers, cylinders, and pipes is a smart choice for their longevity. Nickel coating composites provide exceptional protection against corrosion, wear resistance, and part durability, making them suitable for various types of machinery and industries. However, not all metal plating services can handle long parts, so choosing a provider like Duratech Processes Inc, equipped to meet your needs, is essential. Whether you require oil and gas pipeline coatings or metal plating for steel and stainless steel rollers, Duratech offers the expertise and facilities to ensure your parts are coated to perfection.